Cart upgrades:

Super Carts– Upgrade from OEM unheading cart, stronger 4WD system allows it to move better in coke fallouts and gives better overall support for water and coke fallout.

Crusher Carts– A robust, structurally enhanced cart, that comes standard with stainless steel and grizzly housing to prevent typical corrosion and wear. Hydraulic skirt can be moved up and down, and our larger-bore cylinders provide greater stability for latching.

Forward Assist Carts– For engulfed carts to extract themselves so the skirt can be raised up. All the upgrades and some.

Key features to our systems:

Feedline Alignment System (3-D inlet)

Automated Feedline Clamping System

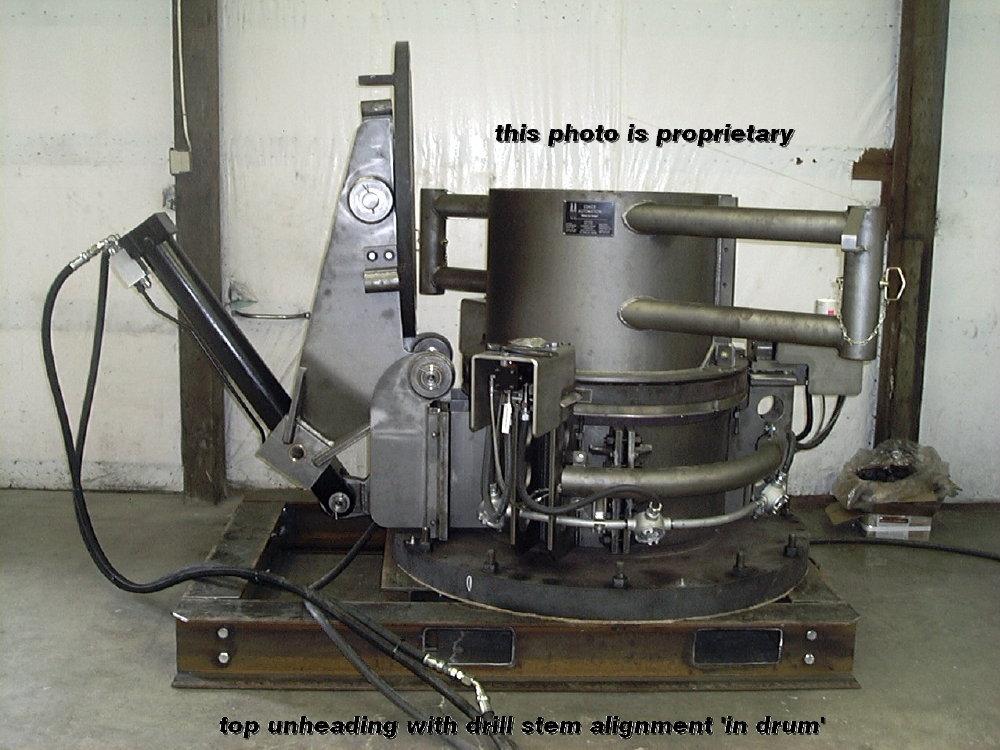

The Delayed Coke Drum "top unheading" device was developed over 25 years ago and has been upgraded many times to increase safety. Since every coker operation is unique to a refinery, modifications can be made to accommodate different top-deck configurations and to provide safe & remote operation of the equipment to provide the best safety application for operating personnel.

Drill Stem Alignment

This technology has undergone multiple modifications to create more efficient devices. Our team will partner with you to determine the best design for your application, to optimize work flow, maximize reliability, and increase safety for the operator.

The proprietary hydraulic system was developed to: